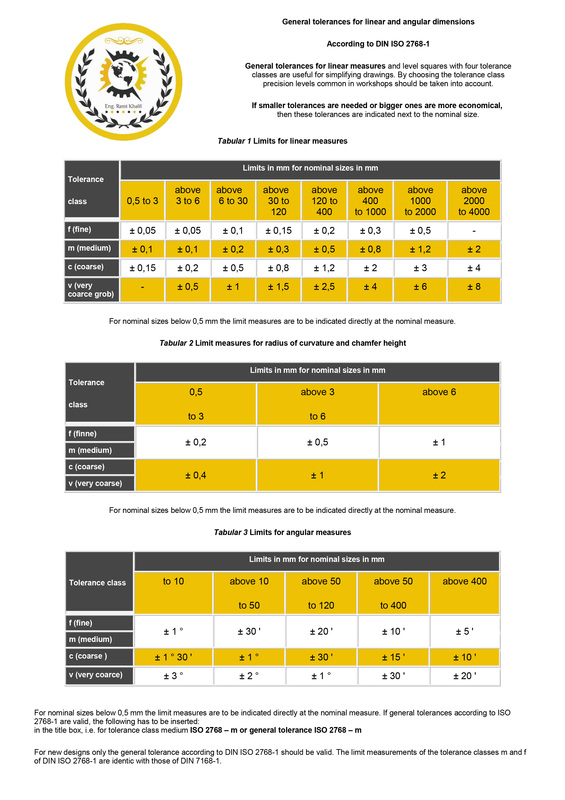

Tolerance grades range from 'A' to 'ZC' for holes, and 'a' to 'zc' for shafts. Additional functionality of ISO 2768 tolerances. Users can now find tolerances for Linear dimensions, Chamfers and Radii, Angles, Straightness, Flatness, Perpendicularity, Symmetry, and run out as defined in ISO 2768 table 1 and table 2. Iso 2768-mh Tolerance Chart IS0 2768-2 2768”; b) the tolerance class Related searches for iso hole tolerances 2768 mk din iso 2768 mk tolerances - practical machinist m. Follow: General tolerances according to DIN ISO 2768-mk 1) Without general tolerances DIN ISO 2768-mK DIN EN ISO 13920-BF NN 14 T. Se Table 1 - Permissible deviations for. General Tolerances to DIN ISO 2768 T1 and T2. The latest DIN standard sheet version applies to all parts made to DIN standards. Variations on dimensions without tolerance values are according to 'DIN ISO 2768-mk'. GENERAL TOLERANCES FOR LINEAR AND ANGULAR DIMENSIONS (DIN ISO 2768 T1). General tolerance ISO 2768 does not specify where to use these tolerances. As per design requirements and manufacturing capability tolerance class is defined. For example: For sheet metal parts ISO 2768–mk is used. And for machined components ISO 2768–fh can be used.